What Is a Gantry Shear Machine and How Does It Work?

In Saudi Arabia’s Metal Recycling and heavy industry sectors, the demand for efficient, safe, and precise cutting solutions is growing rapidly. A gantry shear machine is a critical piece of equipment for scrap metal yards, steel mills, automotive dismantling centers, and aluminum processing plants. It helps businesses process large, bulky, and complex metal materials with high efficiency, while maintaining consistent safety and operational standards.

Understanding Gantry Shear Machines

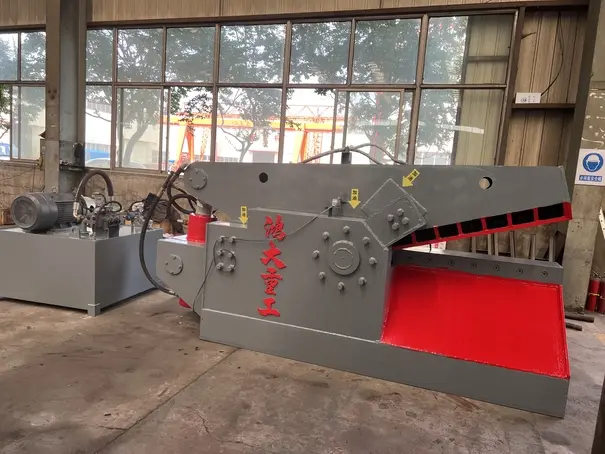

A gantry shear machine is a hydraulic-driven heavy-duty cutting device designed to process large-scale metal scrap and industrial steel. Its gantry-style structure allows the upper cutting blade to move vertically along a guided track, providing high shear force and precise cutting.

Key Functions

Efficient Metal Cutting: Capable of handling thick steel plates, aluminum, copper, and mixed scrap.

Automated or Semi-Automated Operation: Reduces labor input while increasing safety.

Uniform Output: Produces consistently sized metal pieces for further processing or melting.

The main purpose of a gantry shear machine is to convert bulky metal scrap into manageable pieces, optimizing storage, transportation, and recycling workflows.

Applications of Gantry Shears in Industry

Gantry shear machines are widely used across multiple industrial sectors:

Scrap Metal Recycling Companies

Cut mixed steel, aluminum, and copper scrap into standardized sizes for storage and shipment.

Steel Mills & Foundries

Prepare consistent feedstock for melting furnaces, improving operational efficiency.

Automotive Dismantling & ELV Centers

Process vehicle frames, body panels, and engine blocks efficiently, reducing manual labor.

Ports, Yards & Logistics Terminals

Compact scrap metal for export or storage, optimizing transportation space.

Metal Fabrication & Processing Plants

Handle industrial offcuts and scrap to produce reusable metal blocks.

Aluminum Extrusion & Recycling Plants

Efficiently manage aluminum and mixed metal scrap, streamlining pre-melting processes.

Construction & Curtain Wall Companies

Cut and process steel structures for site reuse or waste reduction.

Technical Specifications

Selecting the right gantry shear machine depends on operational requirements. Typical specifications include:

Parameter Specification

Cutting Force 500–800 tons

Blade Width 1,200–1,600 mm

Maximum Cutting Thickness Up to 100 mm (steel plates)

Motor Power 3 × 45 kW

Hydraulic Pumps 3 × A4V250

Shear Frequency 2–3 cuts/minute

Processing Capacity 10–15 tons/hour

Control Full automatic PLC system

Suitable Materials Steel, iron, aluminum, copper, mixed scrap

These parameters ensure high productivity, precise cuts, and long-term operational reliability, even under heavy-duty conditions.

Customer Case Studies

Case 1: Automotive Recycling Plant, Riyadh

Challenge: Processing ELV (End-of-Life Vehicle) frames and panels efficiently.

Solution: Installed a gantry shear to automate cutting.

Result: Reduced labor by 30% and increased processed volume to 12 tons/hour.

Case 2: Steel Mill, Dammam

Challenge: Uniformly sizing thick steel plates for melting.

Solution: Used a gantry shear with high cutting force.

Result: Consistent feedstock improved furnace efficiency and reduced scrap loss.

Case 3: Aluminum Recycling Facility, Jeddah

Challenge: Processing mixed aluminum and steel offcuts for pre-melting.

Solution: Gantry shear installation for automated cutting.

Result: Enhanced pre-melting efficiency, improved recycling rates by 18%.

Benefits of Investing in a Gantry Shear Machine

High Efficiency: Large cutting force ensures fast processing and high throughput.

Safety Assurance: Hydraulic and automated operations reduce human intervention.

Durability: Heavy-duty construction supports long-term operation under continuous use.

Versatility: Handles a wide range of metals and scrap types.

Cost Optimization: Reduces storage needs, labor costs, and transport expenses.

Gantry shear machines are essential tools for the metal recycling, steel production, automotive dismantling, and aluminum processing industries. By efficiently converting large, irregular scrap into manageable, uniform pieces, they optimize workflow, increase productivity, and improve safety. With proven technical specifications and real-world customer success stories, gantry shears represent a smart investment for industrial businesses in Saudi Arabia seeking operational efficiency and long-term reliability.

FAQ

Q1: What is a gantry shear machine used for?

It is used to cut large, thick, or irregular scrap metal into standardized sizes for recycling or industrial processing.

Q2: How does a gantry shear machine work?

A hydraulic system drives the upper blade along a gantry frame, applying consistent shear force to efficiently cut metal.

Q3: Which industries benefit most from gantry shears?

Scrap metal recycling companies, steel mills, automotive dismantling centers, aluminum processing plants, and construction companies.

Q4: What maintenance is required for gantry shear machines?

Regular checks of hydraulic systems, blade sharpness, motor performance, and safety interlocks ensure long-term reliability and efficiency.