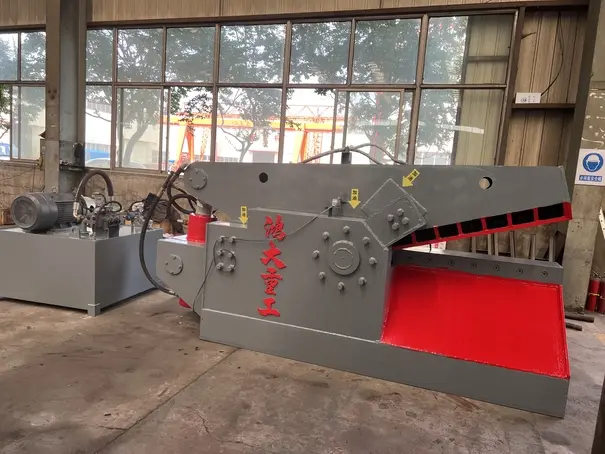

Revolutionizing Industrial Metal Shearing Workflows

In today's fast-paced industrial landscape, Gantry Shears are emerging as essential tools across heavy-duty metal processing industries. With the capacity to rapidly cut thick steel plates, beams, and scrap, they significantly enhance productivity, safety, and operational efficiency. From steel mills and recycling yards to automotive dismantling and port logistics, these machines are reshaping how businesses manage large-scale shearing tasks.

Why Gantry Shears Matter in Heavy Industries

Gantry shears combine powerful hydraulics, rugged frames, and automated controls to offer unmatched performance in:

Speed: Quickly sizing scrap materials to furnace-ready lengths

Precision: Consistent, square cuts minimize post-processing

Safety: Reducing manual sawing and torch-cutting hazards

Scalability: From small shops to mill-scale operations

Given these benefits, gantry shears are ideal for industries dealing with heavy plate or beam cutting operations.

Core Applications of Gantry Shears

- Scrap Metal Recycling Yards

Batch processing of large scrap bundles

Quick sizing for shredders or furnaces

Enhanced sorting, improving downstream efficiency

- Steel Mills & Foundries

Cutting robust steel slabs or rolled beams

Furnace-ready sizing that optimizes melting cycles

Integrating seamlessly with material handling lines

- Auto Dismantling & ELV Centers

Shearing bulk vehicle frames and chassis

A clean alternative to oxy-fuel methods

Reducing labor time and increasing salvage value

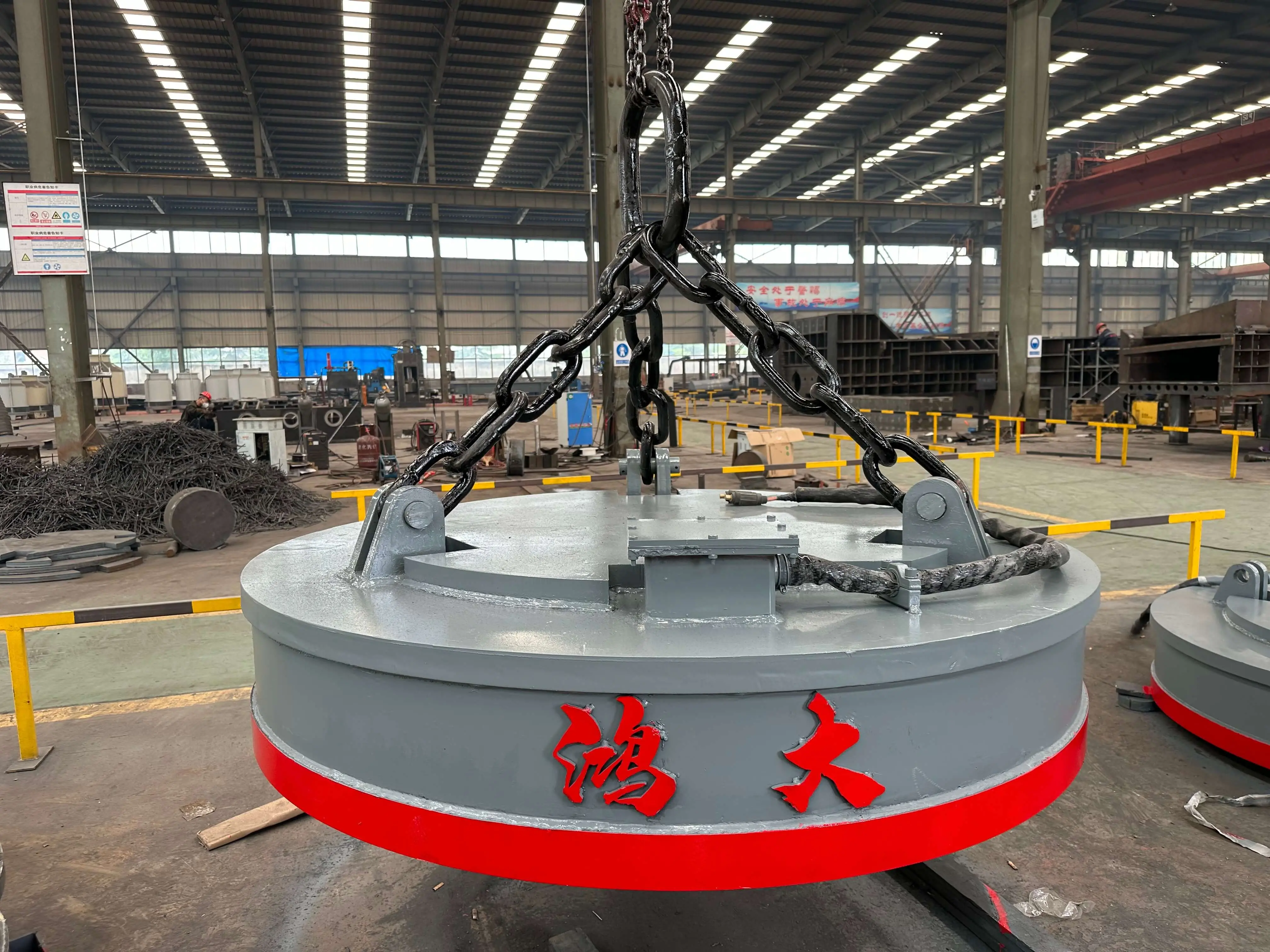

- Ports, Yards & Logistics Terminals

Handling steel plates and bridge sections

Custom cuts for easier transport and stacking

A robust solution for large-scale lifting and shearing

- Metal Fabrication & Processing Plants

Shearing steel for construction or OEM components

Handling irregular, thick profiles in one operation

Boosting throughput in fabrication offices

- Renewable Resource Enterprises

Processing structural steel from decommissioned assets

Reclamation of heavy steel for circular reuse

Enabling green processing with minimal emissions

- Equipment Dealers & Distributors

Offering turnkey gantry shear solutions

Catering to integrators or large-scale industrial buyers

- Aluminum Extrusion & Sheet/Coil Manufacturers

Handling steel packaging or support frames

Maintaining shop-floor order and productivity

- Auto/Aerospace Component Suppliers

Cutting steel fixtures in synchronized production lines

Meeting accuracy demands with reliable cuts

- Construction & Curtain-Wall Companies

On-site shearing of beams, angles, and structural plates

Minimizing manual labor in tight project environments

- Aluminum Scrap Traders & Importers

Precutting mixed scrap bundles for export

Maximizing container load value with precise cuts

How Gantry Shears Work

Feed: Material placed longitudinally—plates, beams, or scrap bundles

Position: Automated grippers or stop guides ensure consistent cuts

Shear: A hydraulic blade descends from the gantry, producing a clean cut

Discharge: Cut sections drop onto conveyors for loading or further processing

Controlled by PLC or touchscreen interfaces

Optional features: auto-lubrication, remote monitoring, safety interlocks

Key Benefits for Indian & Global Industry

Operational Efficiency

Cuts large materials in seconds

Enables batching with minimal setup

Cost Savings

Reduces labor time and secondary cutting

Minimizes consumables like gas due to clean cuts

Safety Improvements

Prevents fire hazards and operator exposure

Integrated emergency shutdown and guarding

Smart Manufacturing

Industry 4.0-ready with remote diagnostics

Predictive maintenance alerts reduce downtime

Environmental Impact

Zero emissions during cutting

Optimizes material recovery for recycling

Best Practice Use-Case: Steel Mill Workflow

Step Description

Receiving Incoming long slabs or beams

Feeding & Positioning Gantry conveyor moves steel into shear station

Cut-to-Length Blade shears pieces to furnace spec

Sorting CNC algorithm directs cut pieces

Melting Clean, sized charges reduce energy usage

This streamlined process boosts throughput by 50%, reduces scrap inventory, and ensures better furnace input.

Industry Trends Driving Adoption

Energy efficiency initiatives in heavy industries

Global recycling mandates, especially in steel and auto waste

Increasing automation in metalworking operations

Higher quality expectations for cut materials and structural integrity

As industries worldwide continue to modernize, gantry shears have become vital assets. Whether producing clean-cut beams for construction, sizing scrap for smelting, or dismantling vehicles at ELV centers, they deliver unmatched efficiency, safety, and precision. Companies that invest in these machines gain a clear competitive edge in today’s fast-paced market.

FAQ

Q1: What materials can gantry shears handle?

They can cut ferrous metals like steel plates, beams, rebar, and thick scrap bundles with consistent quality.

Q2: What plate thickness can a gantry shear manage?

Typical models handle anywhere between 20 mm up to several hundred millimeters—selection depends on hydraulic capacity and blade design.

Q3: Does the shear offer automation features?

Yes, most are equipped with PLC controls, programmable cut lengths, conveyors, and optional remote diagnostics.

Q4: What safety features are standard?

Expect acoustic guards, light curtains, emergency stops, blade locking during maintenance, and overload protection mechanisms.