How to Maintain Your Hydraulic Shear Machine for Maximum Efficiency & Longevity

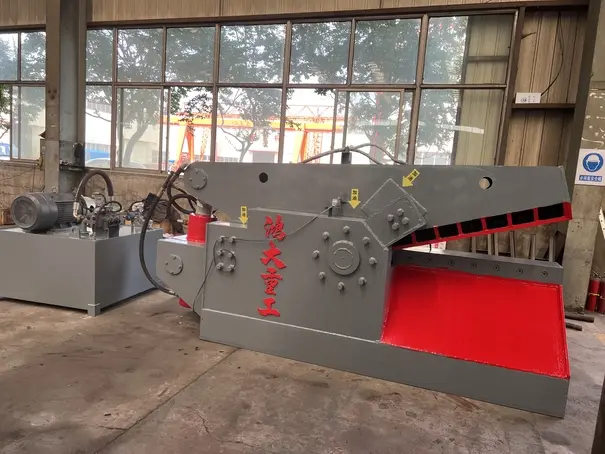

Hydraulic shear machines (such as Alligator Shears, crocodile shears, and guillotine shears) are essential for scrap metal processing, but their performance depends heavily on proper maintenance. Neglecting routine care can lead to downtime, costly repairs, and reduced cutting efficiency.

In this guide, we’ll cover:

✔ Daily, weekly, and monthly maintenance tasks

✔ Common hydraulic shear problems & solutions

✔ Tips to extend your machine’s lifespan

1. Essential Daily Maintenance Checks

To keep your shear running smoothly:

① Inspect Hydraulic Oil Levels

Low oil can cause overheating and pump failure.

Check for leaks around hoses and seals.

Use high-quality anti-wear hydraulic oil (ISO VG 46 or equivalent).

② Monitor Blade Condition

Dull or chipped blades reduce cutting force and waste energy.

Check for wear, cracks, or misalignment.

Rotate or replace blades as needed (most last 6-12 months under normal use).

③ Lubricate Moving Parts

Apply grease to bearings, pivot points, and guide rails.

Use lithium-based grease for high-pressure components.

✅ Pro Tip: Keep a maintenance log to track oil changes, blade replacements, and repairs.

2. Weekly & Monthly Maintenance Tasks

① Clean the Machine Thoroughly

Metal chips and dirt can damage hydraulic systems.

Use compressed air or a brush to remove debris.

② Check Hydraulic Hoses & Fittings

Look for cracks, bulges, or leaks.

Replace damaged hoses immediately to prevent sudden failure.

③ Test Safety Features

Ensure emergency stop buttons, guards, and sensors work properly.

A malfunctioning safety system can lead to accidents and OSHA violations.

3. Common Hydraulic Shear Problems & Fixes

Issue Possible Cause Solution

Slow Cutting Speed Low hydraulic pressure, dirty oil Check pump, change oil, clean filters

Blade Jamming Misaligned blade, worn bushings Realign blade, replace bushings

Oil Leaks Damaged seals, loose fittings Replace O-rings, tighten connections

Overheating Low oil, clogged cooler Top up oil, clean radiator

4. Extending Your Shear’s Lifespan

Use the Right Cutting Capacity → Avoid forcing the machine to cut beyond its rated thickness.

Train Operators Properly → Improper use causes premature wear.

Schedule Professional Servicing → Annual inspections by a technician can prevent major breakdowns.

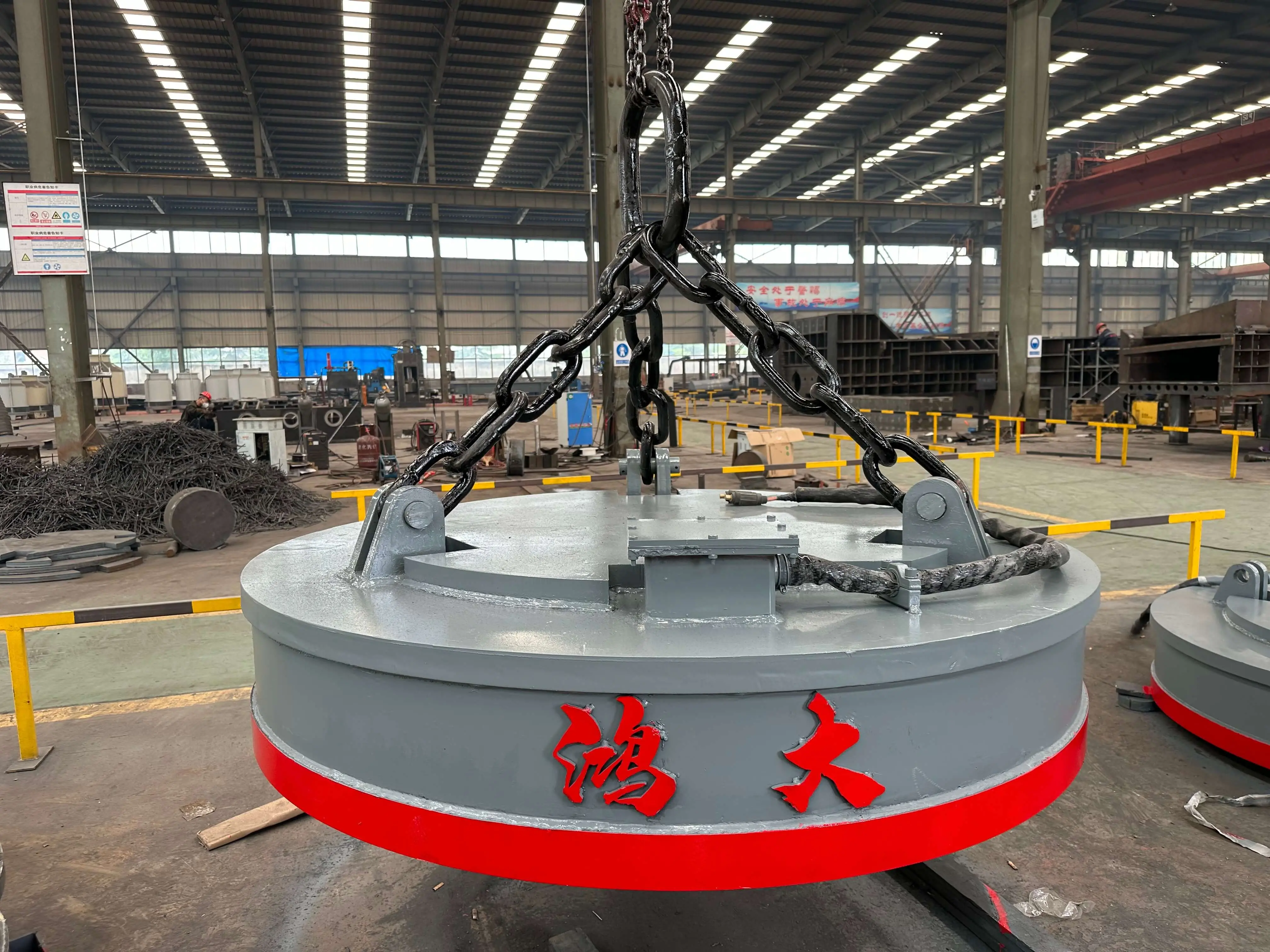

5. Why Choose Hongda Heavy Industry’s Shear Machines?

At Shandong Hongda Heavy Industry, we design our alligator shears, guillotine shears, and crocodile shears for:

✔ Heavy-duty performance (up to 500+ tons cutting force)

✔ Easy maintenance (accessible components, durable materials)

✔ Long-term reliability (CE-certified, ISO-compliant)

Need spare parts or technical support? Contact our team for expert assistance!