Powering Brazil's Recycling Efficiency: How Metal Balers Streamline Scrap Handling and Processing

In Brazil's rapidly industrializing sectors—from automotive dismantling in São Paulo to aluminum smelting in Minas Gerais—Metal Balers are indispensable tools. These machines compress loose scrap metal into dense, uniform bales that are easier to handle, transport, and melt down. Whether you operate a recycling plant, a foundry, or a port logistics terminal, integrating a metal baler into your workflow boosts operational efficiency, safety, and profitability.

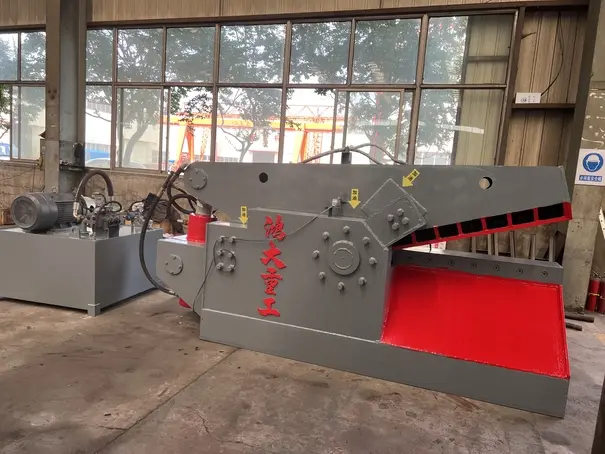

What Is a Metal Baler and Why Does It Matter?

A metal baler is a hydraulic machine that compacts various types of scrap metal into tightly packed bales. These bales can be rectangular, cylindrical, or square, depending on the application. In Brazil, where scrap export volumes and internal consumption are rising, metal balers help streamline operations across a wide range of sectors:

Reduce storage and transport costs

Prepare scrap for melting or resale

Improve workplace safety

Enhance recycling profitability

Whether you’re managing steel beams at a foundry or aluminum sheets at a fabrication plant, metal balers offer practical advantages for heavy-duty operations.

How Metal Balers Work: Step-by-Step Process

Modern Hydraulic Metal Balers typically follow this workflow:

Feeding Scrap Metal

Operators load materials into the baling chamber manually, with a grab, or via a conveyor.

Compression Sequence

Hydraulic rams comPress Scrap from three directions: side, top, and front.

Forming the Bale

Scrap is squeezed into a dense, pre-defined shape.

Bale Ejection

A hydraulic door opens or an automatic ejector pushes the bale out.

This fully hydraulic process minimizes manual effort, reduces material spring-back, and ensures consistent bale density.

Industrial Applications in the Brazilian Market

Metal balers serve a wide range of heavy industries in Brazil:

Scrap Metal Recycling Companies

Compress loose ferrous and non-ferrous scrap

Increase container load capacity for export

Enable automated, high-volume sorting

Steel Mills & Foundries

Prepare furnace-ready feedstock

Reduce melting energy consumption

Improve scrap yield and casting quality

Auto Dismantling & ELV Centers

Bale vehicle bodies, frames, and engine blocks

Simplify transport to shredding or smelting lines

Reduce labor and forklift usage

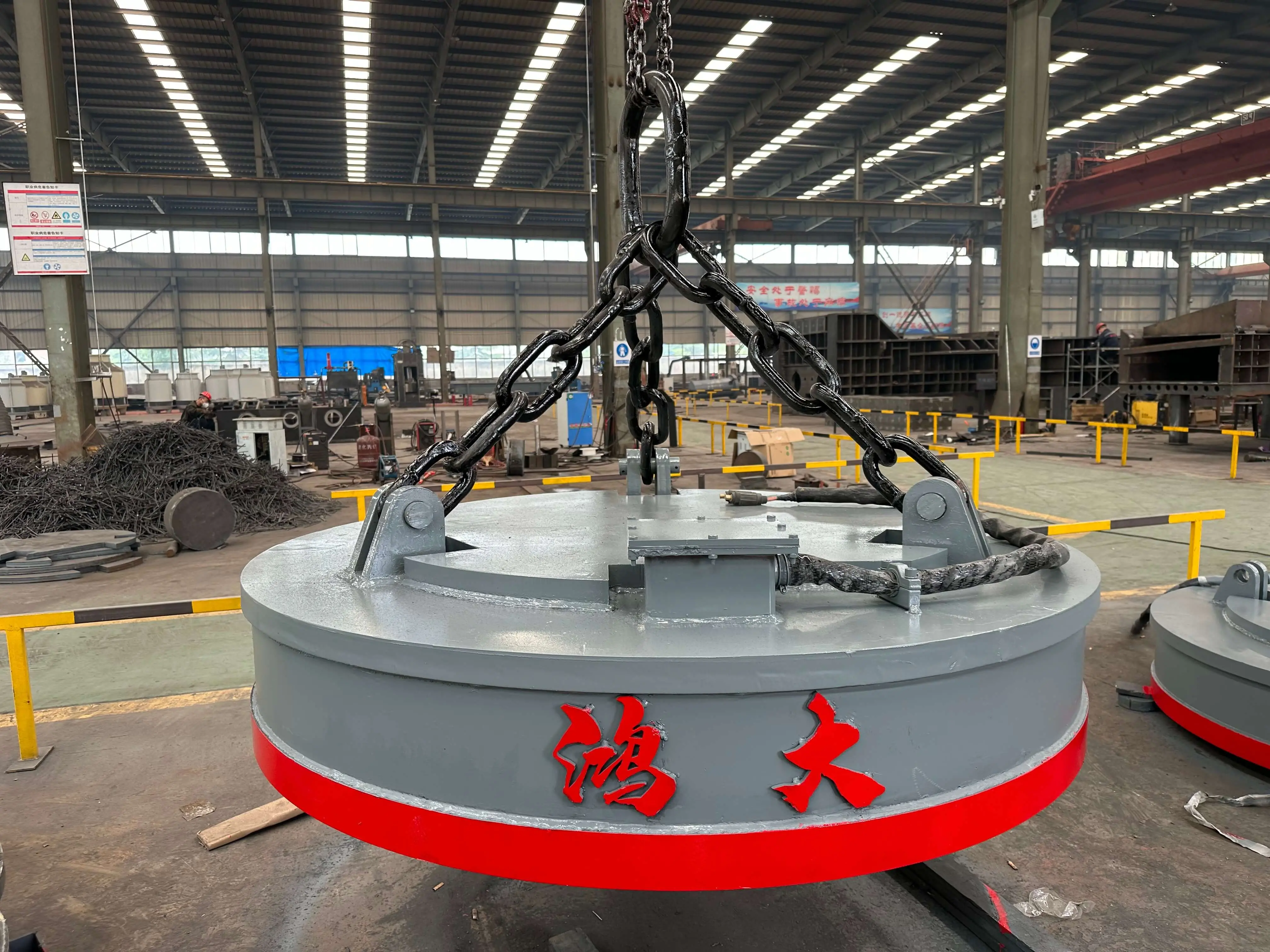

Ports, Yards & Logistics Terminals

Package metal scrap for efficient container loading

Lower shipping costs via compact bales

Improve handling time and site safety

Aluminum Recycling & Extrusion Plants

Compress aluminum offcuts, cans, or profiles

Enhance smelting efficiency with uniform bale density

Reduce oxidation and energy usage during melting

Key Performance Advantages of Modern Metal Balers

Brazilian manufacturers and recyclers face rising labor costs and logistics challenges. A well-engineered metal baler can make all the difference.

1. High Efficiency

Fast cycle times with programmable control

Integrated conveyors for automatic feeding

Capable of processing up to 8–12 tons per hour

2. Versatility

Handles a wide variety of metals:

▸ Steel

▸ Copper

▸ Aluminum

▸ Stainless

▸ Light iron

3. Durability & Low Maintenance

Wear-resistant blades and plates

Industrial-grade hydraulics with high working pressure

Simple service points and diagnostics

4. Space & Cost Savings

Reduce scrap volume by up to 85%

Lower warehouse footprint for storage

Cut fuel and transport costs by minimizing haul weight

Customizing the Right Metal Baler for Your Business

When choosing a metal baler for your Brazilian facility, consider:

Bale Size & Output Requirements

Choose based on containerization standards and melt furnace size.

Material Types

Some balers are optimized for aluminum, while others handle heavy steel.

Automation Level

Fully automatic balers are ideal for high-throughput operations.

Discharge Type

Push-out, side-eject, or turn-out mechanisms depend on floor space and workflow.

Local Support

Ensure the manufacturer offers Portuguese-language manuals, training, and parts availability in Brazil.

Real-World Example: Automotive Scrap Plant in Paraná

A recycling firm in Curitiba, Paraná, installed a 160-ton horizontal metal baler to process car shells and engine blocks. Results within 6 months:

30% increase in processing volume

Fuel costs reduced by 25% due to compact bale logistics

99% uptime with minimal maintenance

This investment helped the company secure contracts with two foundries and boosted overall profitability.

Metal Balers Are the Backbone of Efficient Scrap Management

From São Paulo’s recycling yards to Manaus’ aluminum plants, metal balers are helping Brazilian industries become more competitive, sustainable, and efficient. These machines not only reduce operating costs but also support circular economy goals. If your business handles large volumes of scrap, a metal baler is not just an upgrade—it’s a strategic asset.

Frequently Asked Questions (FAQ)

Q1: What types of metal can be baled?

A: Metal balers can compress a variety of materials including steel, copper, aluminum, brass, and stainless steel. Ensure your baler is rated for your specific scrap type.

Q2: Do metal balers require a large space?

A: No. Horizontal and vertical models are available in different sizes. Compact balers are ideal for urban or limited-space operations.

Q3: How much power does a hydraulic metal baler consume?

A: It varies by model. A 125–160 ton baler may use a 30–45 kW motor. Models can be tailored for Brazil’s 220V/380V three-phase power supply.

Q4: Can metal balers be integrated into automated lines?

A: Yes. Many balers offer PLC control and can be connected with conveyors, sensors, and remote operation systems for fully automated scrap handling.