Metal Baling Machine: How It Works, Applications and Benefits

Learn how Metal Baling Machines compress scrap metals efficiently. Discover applications, benefits, and industry insights for recycling, steel, and auto dismantling.

How Does a Metal Baling Machine Work? A Complete Guide for Industrial Recycling

September 2025 – Singapore – In today’s recycling and metal processing industries, efficiency, cost reduction, and sustainability are top priorities. Scrap metals such as steel, aluminum, and copper occupy significant space and are costly to transport in raw form. A metal baling machine solves this challenge by compressing loose scrap into dense, uniform bales, simplifying handling, storage, and improving downstream recovery in smelting and foundry operations.

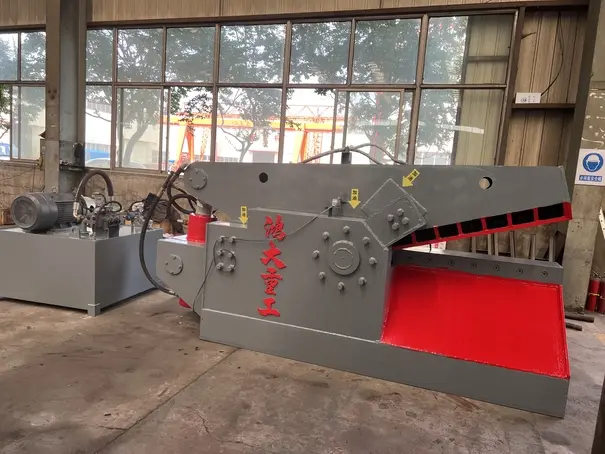

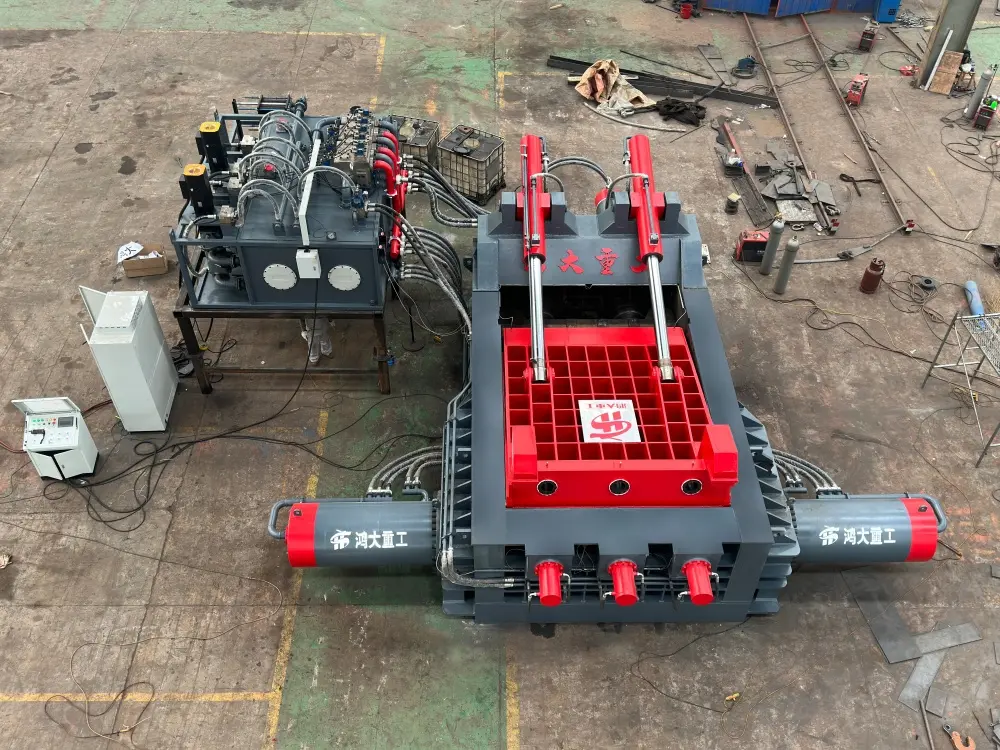

How a Metal Baling Machine Works

A metal baling machine operates on hydraulic compression technology, applying high pressure to transform bulky scrap into compact bales. The process can be broken down into four main stages:

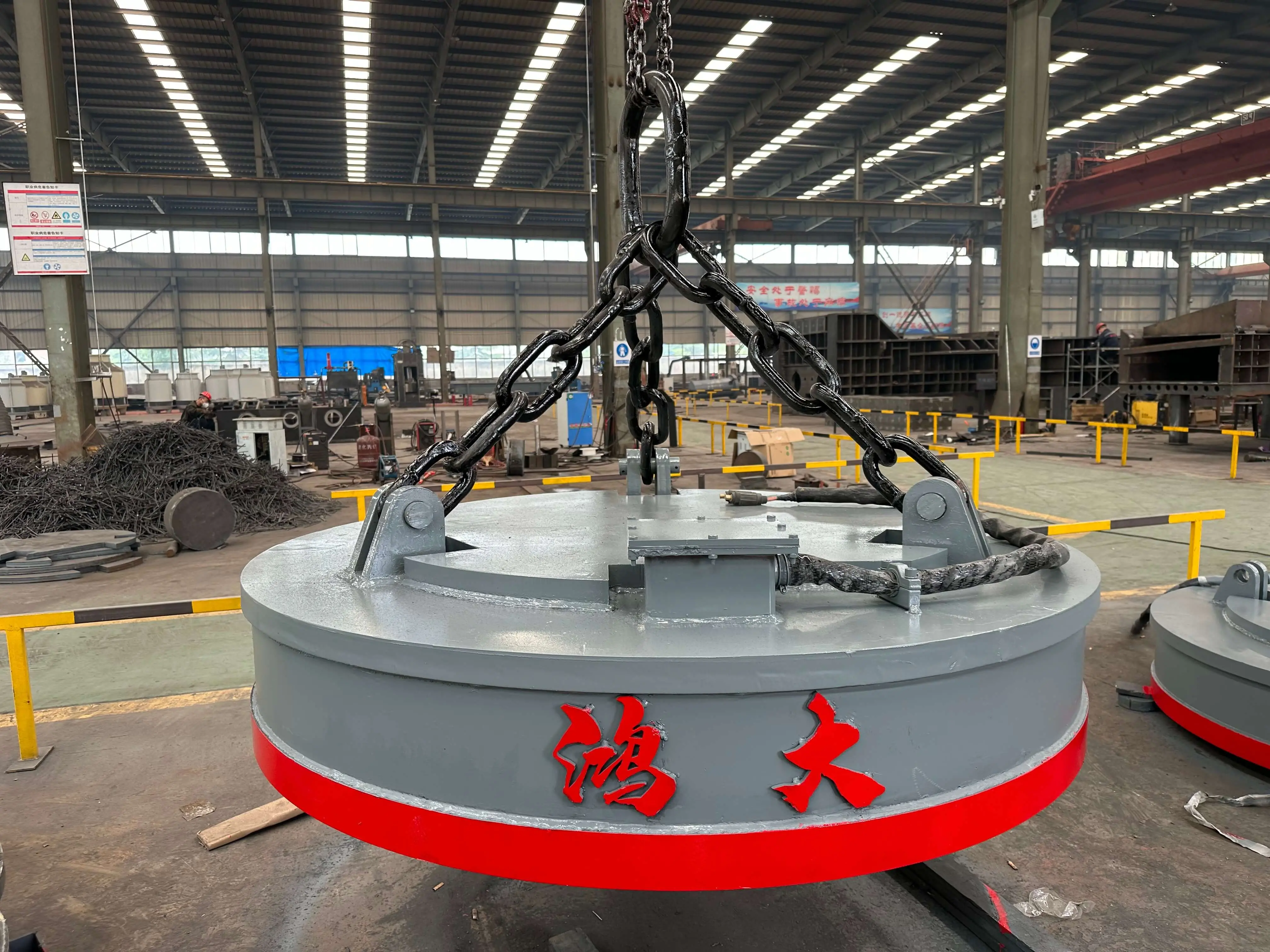

Feeding – Scrap is loaded manually, by conveyor, or with cranes and grabs.

Compression – Hydraulic cylinders apply high pressure, reducing volume by up to 70%.

Bale Formation – Scrap is shaped into rectangular or cylindrical bales depending on the model.

Discharge – Finished bales are ejected automatically or manually for transport and storage.

Unlike paper or plastic balers, Metal Balers feature reinforced steel chambers and high-tonnage hydraulic systems to withstand the extreme forces required for dense metals.

Key Technical Parameters

Parameter Range / Description

Pressing Force 63–2000 tons

Bale Size 300×300 mm up to 800×800 mm (customizable)

Production Capacity 3–25 tons per hour

Drive System Hydraulic (manual, semi-automatic, or PLC-controlled)

Power Requirement 22–200 kW

Applicable Materials Steel, aluminum, copper, car shells, stainless steel, light metals

Industrial Applications

Scrap Metal Recycling Companies – Compress mixed ferrous and non-ferrous scrap into high-density bales, improving resale value and reducing shipping costs.

Steel Mills & Foundries – Furnace-ready bales allow faster charging, uniform melting, and lower energy consumption.

Auto Dismantling & ELV Centers – Process car bodies, engine blocks, and structural scrap, simplifying shredding and downstream recycling.

Ports, Yards & Logistics Terminals – Handle imported/exported scrap in bulk, maximizing container efficiency.

Aluminum & Non-Ferrous Metal Recycling – Compact aluminum sheets, coils, and extrusion profiles, supporting sustainability goals in supply chains.

Benefits of Using a Metal Baler

Space Optimization: Reduce scrap volume by 50–70%.

Transportation Savings: Denser bales lower freight costs.

Operational Efficiency: Continuous automated operation boosts throughput.

Durability: Heavy-duty frames and hydraulic systems ensure longevity.

Environmental Compliance: Supports recycling targets and circular economy goals.

Choosing the Right Metal Baler

Material Type: Steel, aluminum, copper, or mixed scrap.

Production Output: Daily or hourly processing needs.

Bale Density & Size: Suitable for your furnace, smelter, or transport system.

Automation Level: Manual, semi-automatic, or fully automated.

After-Sales Service: Availability of spare parts, training, and technical support.

Market Insight

According to Market Research Future (2024), the global scrap metal recycling market is projected to reach USD 550 billion by 2030, driven by increasing demand from steel mills, automotive recycling, and sustainable manufacturing practices. This growth underscores the importance of metal baling machines for efficiency and cost savings in the industry.

Why Metal Balers Are Essential

Metal baling machines are vital tools in modern scrap management. They help recycling companies, steel mills, and auto dismantlers achieve cost savings, streamlined logistics, and environmental compliance. Understanding how a metal baling machine works ensures buyers select the right equipment to meet current demands and long-term sustainability goals.

Frequently Asked Questions (FAQ)

Q1: What materials can a metal baling machine compress?

A: It can handle ferrous and non-ferrous metals, including steel, aluminum, copper, car shells, and stainless steel.

Q2: How is a metal baler different from a paper or plastic baler?

A: Metal balers are built with reinforced structures and high hydraulic pressure to handle dense, heavy materials.

Q3: What industries benefit most from metal balers?

A: Scrap yards, steel mills, auto dismantling facilities, aluminum recycling plants, and ports/logistics terminals.

Q4: What is the typical lifespan of a metal baler?

A: With proper maintenance, a high-quality baler can operate effectively for 10–15 years or longer.