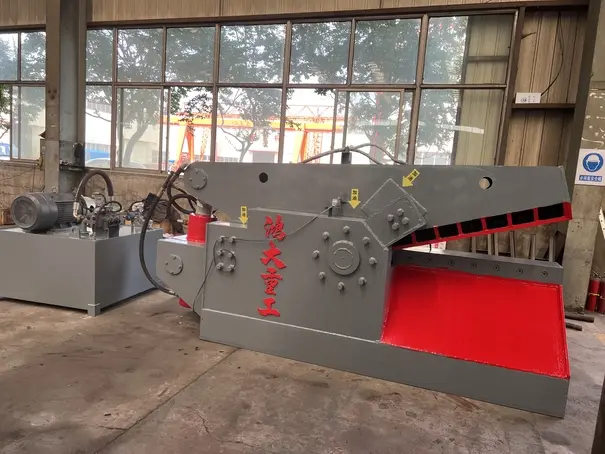

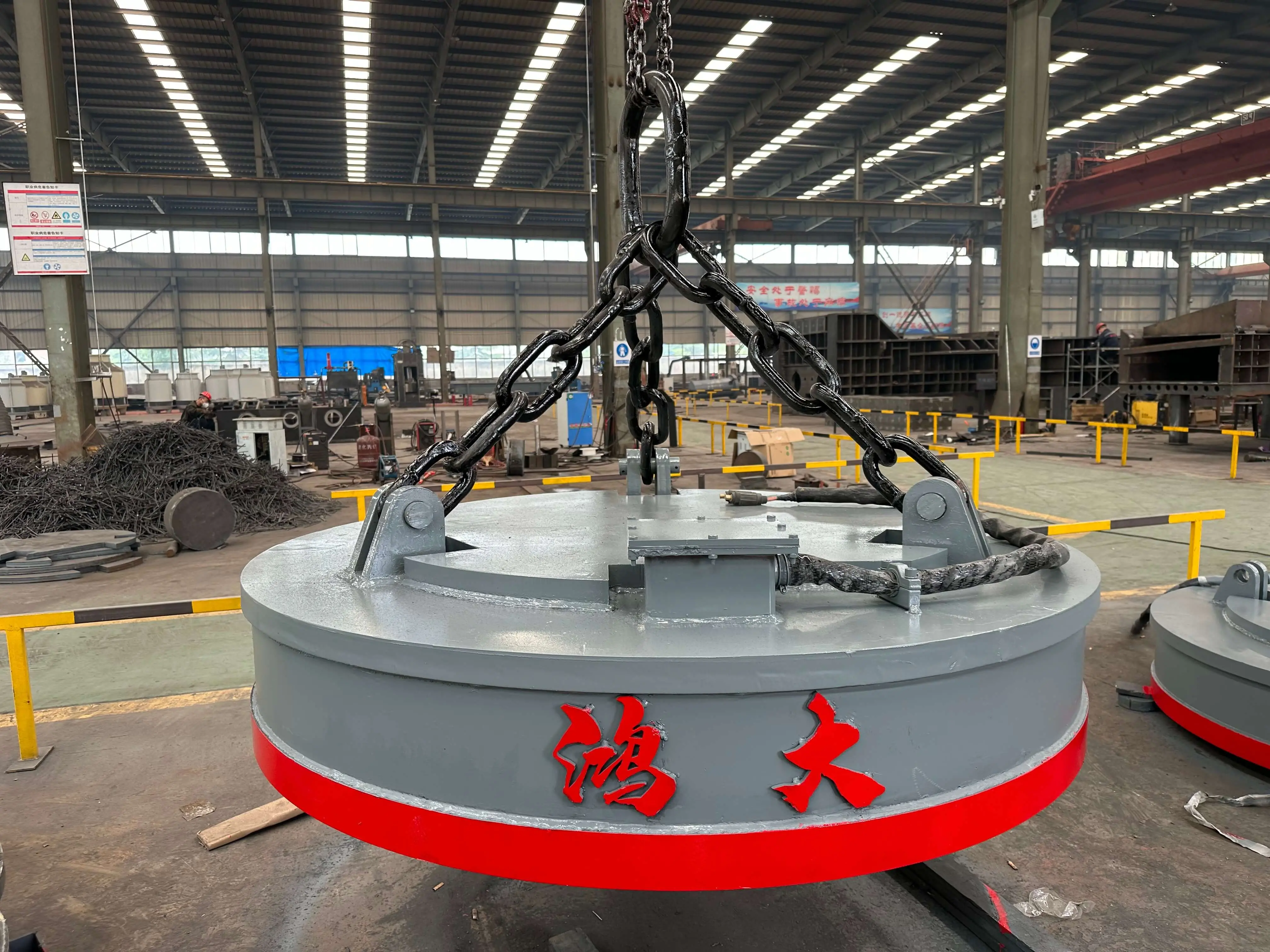

Efficient Scrap Management with Advanced Metal Baling Machines

Modern Metal Recycling operations demand equipment that balancesefficiency, space optimization, and eco-friendly performance.

A Metal Baling Machine delivers exactly that — compressing bulky, irregular metal waste into dense, transportable bales that simplify handling, storage, and logistics.

Designed for long-term reliability, it’s an essential solution for industries where scrap metal management is a daily challenge.

Product Features

1. High Compression Efficiency

The machine uses powerful hydraulic cylinders to generate immense pressure, compressing loose scrap into compact bales that save up to 80% storage space and reduce freight costs.

2. Sturdy and Reliable Construction

Each baler is built from heavy-duty steel and precision-engineered components to withstand continuous industrial operation with minimal maintenance.

3. Flexible Operation Modes

Available in horizontal, vertical, and triple-action configurations, the baler adapts easily to different scrap types — steel, copper, aluminum, or mixed materials.

4. Intelligent Hydraulic System

A modern hydraulic control system ensures stable pressure output and energy efficiency, delivering consistent bale density while minimizing power consumption.

5. Safety and Automation Options

Equipped with automatic feeding, pressing, and discharge systems, the baler reduces manual handling, improves safety, and increases overall productivity.

Applications

A Metal Baling Press is designed to handle a wide range of ferrous and non-ferrous materials.

It is widely used for:

-

Compressing steel plates, iron scraps, and machining offcuts

-

Recycling aluminum profiles, copper wires, and radiators

-

Managing automotive dismantling waste and demolition metal

-

Preparing feedstock for steel mills and foundries

-

Improving storage and transport efficiency in scrap recycling centers

Whether you’re processing light scrap from workshops or heavy materials from demolition projects, a Metal Baler ensuresuniform, dense bales ready for transport or direct smelting.

Industry Fields

The metal baling machine plays a vital role across multiple industrial sectors:

-

Metal Recycling & Waste Management – Transforming loose scrap into transportable blocks.

-

Automotive & Machinery Dismantling – Compressing frames, car bodies, and engine parts.

-

Manufacturing & Fabrication Plants – Handling leftover steel cuttings and production waste.

-

Steel Mills & Foundries – Feeding pre-compressed metal directly into furnaces.

-

Construction & Demolition Sites – Managing large-volume metal debris safely and efficiently.

These industries rely on Hydraulic Balers to optimize recycling value, reduce logistics costs, and maintain environmental compliance.

The metal baling machine is more than just recycling equipment — it’s a strategic investment in efficiency, safety, and sustainability.

By converting waste metal into compact, high-density bales, it optimizes every stage of recycling, from collection to remelting.

For manufacturers, recyclers, and demolition contractors seeking reliable metal recycling machinery, this baler offers a practical, cost-effective, and environmentally responsible solution.

FAQs

Q1: What is the main purpose of a metal baling machine?

A1: Its main function is to compress loose scrap metal into dense, manageable bales for easier storage, handling, and transport — significantly improving recycling efficiency.

Q2: Can a metal baler handle both ferrous and non-ferrous metals?

A2: Yes. The machine is suitable for a wide range of materials, including steel, aluminum, copper, stainless steel, and iron, making it ideal for diverse recycling operations.

Q3: How does a hydraulic metal baler reduce operational costs?

A3: By increasing scrap density, it cuts down transportation and storage expenses while minimizing manual labor — boosting overall recycling profitability.

Q4: Is customization available for different scrap processing needs?

A4: Absolutely. Manufacturers can tailor bale size, compression force, and automation level to meet your production capacity and material type.