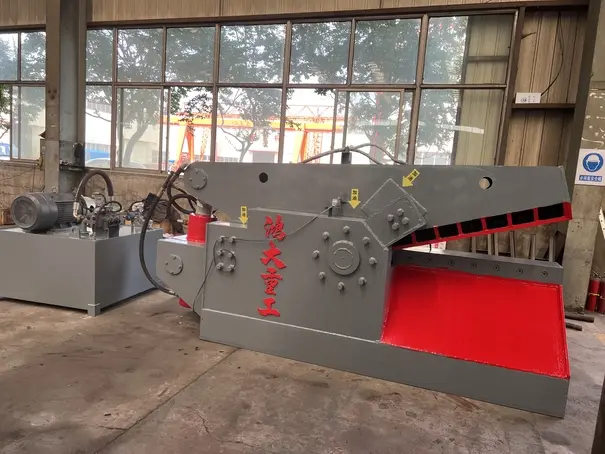

Alligator Shears: Precision Cutting for Efficient Scrap Metal Management

In the fast-paced industrial and recycling sectors of Brazil, efficiency, safety, and precision are essential for handling large volumes of metal scrap. Alligator Shears are designed to meet these needs, providing heavy-duty cutting capabilities for a variety of ferrous and non-ferrous materials. From scrap yards to steel mills, these machines streamline operations, reduce labor costs, and enhance overall productivity.

What is the Purpose of Alligator Shears?

Alligator shears are primarily used to cut large, heavy, or awkward metal pieces into manageable sizes for recycling or further processing. They are ideal for:

Scrap Metal Recycling Companies:Cutting steel plates, rods, and beams for efficient sorting and processing.

Steel Mills & Foundries: Breaking down castings, structural steel, and furnace-ready scrap.

Auto Dismantling & ELV Centers: Cutting vehicle frames, engine blocks, and scrap components safely and efficiently.

Ports, Yards & Logistics Terminals: Preparing metal bundles for transportation and storage.

Metal Fabrication & Processing Plants: Reducing metal offcuts and large sheets for easier handling and production integration.

Alligator shears excel at processing thick, tough metals that are difficult to handle manually, making them a cornerstone of modern metal recycling and fabrication operations.

Key Applications of Alligator Shears

The versatility of alligator shears makes them suitable for numerous industrial scenarios:

Scrap Metal Handling: Cut and prepare scrap steel, iron, and mixed ferrous materials for melting or resale.

Automotive & Aerospace Component Processing: Efficiently segment car frames, aircraft parts, and aluminum scrap for recycling or refurbishment.

Steel Plate & Structural Metal Processing: Reduce heavy steel sheets, beams, channels, and plates to manageable sizes.

Foundry Operations: Handle raw castings and furnace feedstock, improving melting efficiency and safety.

Construction Waste Recycling: Cut steel rebar, beams, and framework from demolition sites into reusable pieces.

Technical Specifications

Alligator shears are built for strength, reliability, and precision. Typical specifications include:

Specification Details

Model Industrial Alligator Shear

Cutting Force Up to several hundred tons, model-dependent

Maximum Cutting Thickness Up to 100–150 mm (steel)

Blade Length 1600–2500 mm

Motor Configuration 45–75 kW, depending on model

Hydraulic Pump Type A4V series or equivalent

Control System Fully automatic or semi-automatic PLC control

Operation Mode Manual feed, crane-assisted, or automated

Safety Features Overload protection, emergency stop

These specifications ensure alligator shears handle high-density, large-volume scrap efficiently while maintaining operator safety and machine longevity.

Customer Success Stories

Recycling Plant, São Paulo: Implemented alligator shears for steel plate processing, improving throughput by 35% and reducing manual labor.

Automotive Dismantling Facility, Curitiba: Automated car frame and engine block cutting, reducing cycle time and minimizing operator risk.

Steel Mill, Rio de Janeiro: Integrated shears into furnace feed preparation, ensuring uniform scrap sizes and improving melting efficiency.

Construction Scrap Recycling, Belo Horizonte: Cut demolition steel beams and rebar, increasing storage density and facilitating resale.

Why Invest in Alligator Shears?

Investing in alligator shears provides multiple operational benefits:

High Cutting Efficiency: Reduce large, heavy metal pieces into manageable sizes quickly.

Enhanced Safety: Minimize manual handling and prevent accidents with robust safety features.

Versatility: Suitable for a wide range of metal types, including steel, iron, aluminum, and mixed scrap.

Automation-Ready: Can integrate with gantry cranes, conveyors, and PLC systems for fully automated operations.

Durability: Built with reinforced steel structures and high-quality hydraulic components for long-term reliability.

Alligator shears are essential tools for B2B industrial operations involving heavy metal handling. From scrap yards to steel mills, auto dismantling centers to construction recycling operations, these machines improve efficiency, safety, and productivity. For Brazilian industrial operators, investing in a high-quality alligator shear ensures faster processing, lower labor costs, and optimized metal recycling workflows.

FAQ

Q1: What is the primary purpose of alligator shears?

A: To cut large, heavy, or irregular metal pieces into manageable sizes for recycling, fabrication, or furnace feeding.

Q2: Can alligator shears handle both ferrous and non-ferrous metals?

A: Yes, they are designed to cut steel, iron, aluminum, and other scrap materials, depending on the model and blade configuration.

Q3: How are alligator shears operated safely?

A: With automatic or semi-automatic controls, safety interlocks, emergency stops, and overload protection to reduce operator risk.

Q4: What industries benefit most from alligator shears?

A: Scrap metal recycling, steel mills, auto dismantling, aluminum processing, construction recycling, and metal fabrication industries.